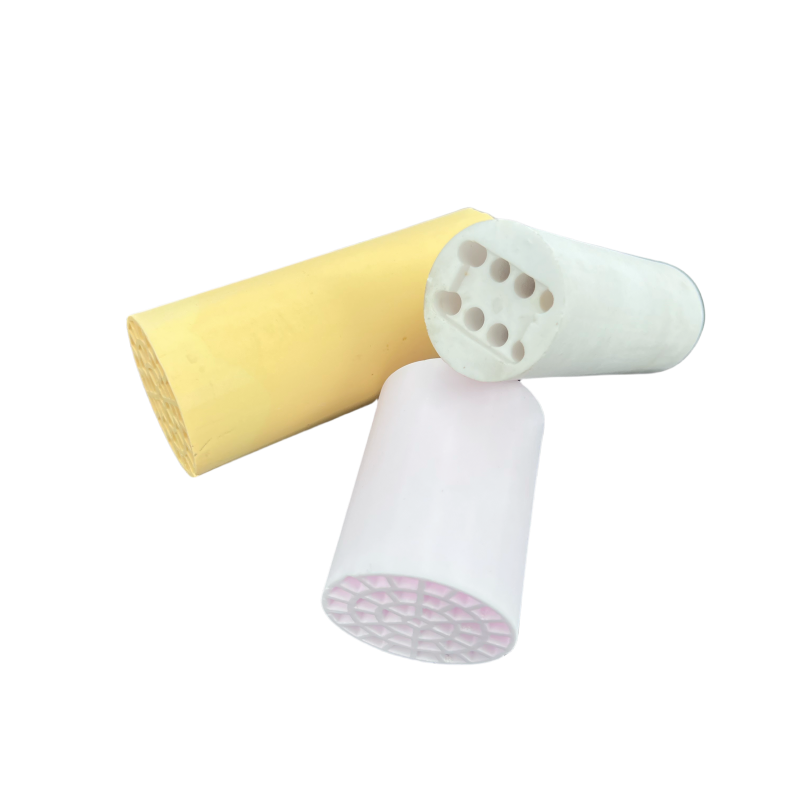

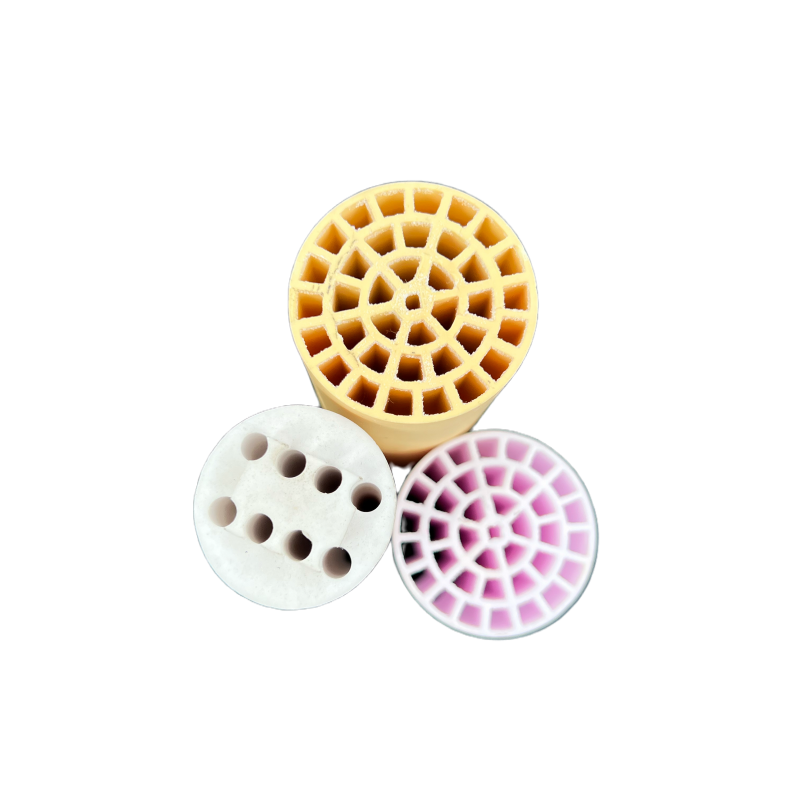

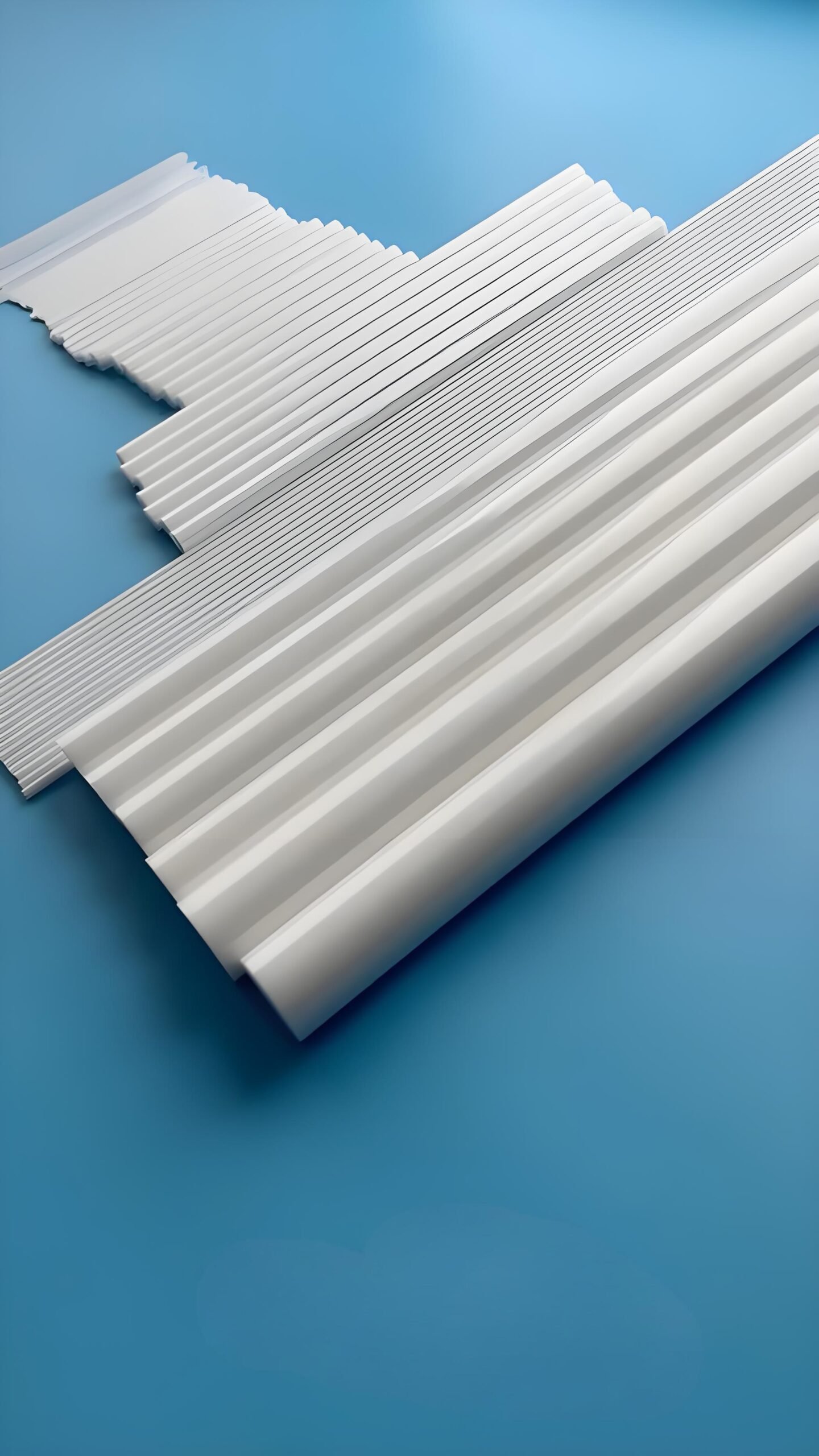

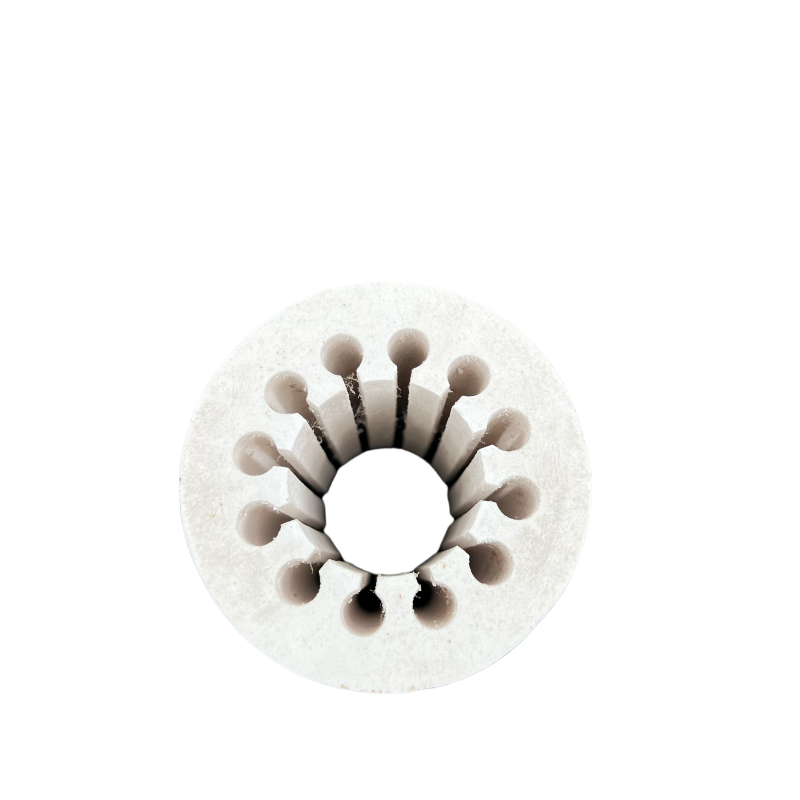

Our High Temperature Resistant Refractory Porous Mullite Ceramics are engineered to meet the most demanding industrial applications where extreme heat resistance, thermal insulation, and structural integrity are critical. Manufactured using advanced sintering technology, these ceramics feature a highly porous structure with excellent thermal shock resistance and low thermal conductivity, making them ideal for use in kilns, furnaces, thermal reactors, and filtration systems.

- Excellent High-Temperature Performance: Stable operation at temperatures up to 1700°C.

- Superior Thermal Insulation: Low thermal conductivity reduces heat loss and energy consumption.

- Lightweight & High Strength: Optimized porosity ensures a balance between strength and insulation.

- Corrosion & Erosion Resistant: Withstands harsh chemical environments and thermal cycling.

- Customizable Shapes & Sizes: Available in bricks, plates, tubes, and custom geometries for various industrial needs.