-

Industrial Alumina Ceramics: Performance, Manufacturing Stability, and Procurement Guidance

2025-11-21In the 1600°C Sintering Furnace, What Determines Batch Stability of Alumina Ceramics? It's not only raw material purity—it's the precise replication of heating ramps, hold times, and cooling rates. A density fluctuation of just 0.1 g/cm³ in alumina ceramic shifts the dielectric strength of high-voltage insulator rings by 3–5 kV/mm. Uncontrolled grain growth can slash the service life of wear-resistant bushings by over 40%. These ...

-

From 0.5mm to 100mm: Custom Diameter Zirconia Ceramic Rods for Diverse OEM Requirements

2025-11-14At Norke Ceramics—a specialized technical ceramics manufacturer with 15+ years of zirconia processing expertise—we've eliminated the compromise between material performance and size availability. Our in-house produced yttria-stabilized zirconia (YSZ) ceramic rods are now precision-manufactured across a continuous diameter spectrum, ranging from 0.5mm micro-components to 100mm heavy-duty bushings, utilizing identical material batchin...

-

High-Temperature Cordierite Electric Ceramics for Industrial Heating Systems – Performance Advantages, Applications, and OEM Supply Solutions

2025-11-07In industrial heating systems, the choice of ceramic materials directly affects heating efficiency, equipment stability, and long-term operational safety. Among various technical ceramics used in electric heating components, cordierite ceramics have gained significant attention from global manufacturers due to their low thermal expansion, excellent thermal shock resistance, and cost efficiency. As large-scale industrial heating s...

-

Semiconductor Ceramics Factory & Exporter: A Case Study on New Energy Systems Manufacturer

2025-10-30The Client's Needs and Challenges Our client, a manufacturer in the renewable energy sector, specializes in creating innovative solutions for solar and wind energy production. With the growing demand for renewable energy solutions, they faced the challenge of improving the energy efficiency and durability of their solar and wind power systems. They sought ceramic materials that could withstand high temperatures, humidity, and ...

-

What is the difference between high-purity alumina ceramics and standard-grade alumina ceramics?

2025-10-22I. Composition and Purity High-purity alumina ceramics: Contain over 99.9% Al₂O₃ with virtually no impurities. Standard alumina ceramics: Classified by Al₂O₃ content as 99% alumina, 95% alumina, 90% alumina, 85% alumina, etc. Sometimes, even ceramics with 80% or 75% Al₂O₃ are categorized under standard alumina ceramics. II. Performance Comparison 1. Hardness High-purity type: Rockwell hardness of HRA 80-90, second onl...

-

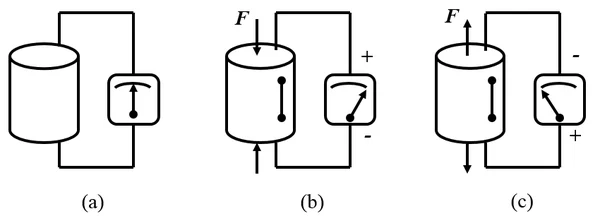

Detailed Explanation of Vibration Direction in Tubular Piezoelectric Ceramics

2025-10-13Piezoelectric Effect and Its Principle The principle of the piezoelectric effect is that applying pressure to a piezoelectric material generates an electric potential difference (known as the direct piezoelectric effect). Conversely, using an electric voltage produces mechanical stress (known as the inverse piezoelectric effect). In other words, piezoelectric ceramics possess the ability to convert mechanical energy into electric...

-

Functions, Applications, and Production Process of Alumina Ceramic Materials

2025-10-13Introduction to Alumina Ceramic Materials Alumina ceramics are industrial oxide ceramics composed of aluminum oxide (Al₂O₃). Different series of alumina materials can be produced based on the percentage of Al₂O₃ content and the type of additives used. Classified by Al₂O₃ content, grades include 75%, 85%, 95%, and 99%. Based on crystalline phase differences, types encompass mullite, corundum-mullite, and pure corundum. By introduc...

-

Electronic Ceramics: Insulator? Semiconductor?

2025-10-13Electronic Ceramics: Electronic ceramics refer to various ceramics applied in electronic technology, specifically ceramic materials used in the electronics industry to manufacture electronic components and devices. They are generally categorized into structural ceramics and functional ceramics (primarily electrically functional). Structural ceramics denote ceramic materials used to produce substrates, housings, fasteners, and ins...

-

Common Issues and Causes in the Sintering of Zirconia Industrial Ceramics

2025-10-10I. Deformation of Zirconia Industrial Ceramics Deformation occurring during the sintering process of zirconia industrial ceramics may result from an extensive particle size distribution, improper selection or excessive addition of additives in the powder, or inconsistent shrinkage of the zirconia industrial ceramics. Causes of Inconsistent Shrinkage in Zirconia Industrial Ceramics: ① Uneven furnace temperature causes incons...

-

Applications of Ceramic Fiber Materials in Refractory Fields

2025-05-15Ceramic fiber materials are widely used in refractory applications due to their excellent thermal insulation properties, high-temperature resistance, and lightweight nature. They play a critical role in industries that require materials to withstand extreme heat while minimizing energy loss. Key Applications: Thermal Insulation in Furnaces and KilnsCeramic fibers are commonly used to line industrial furnaces, kilns, and b...

YIXING NORKE

-

WhatsApp: +8613601538630 -

Phone: +8613601538630 -

Email: shx@norkeceramics.com