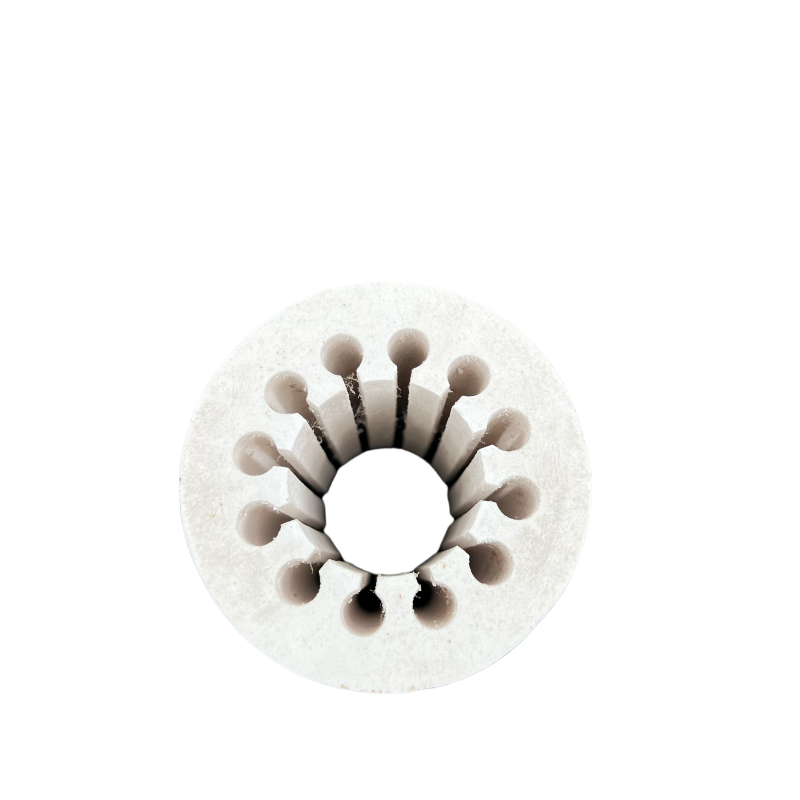

カラーコード付きジルコニアセラミックロッド卸売 | 工業用YSZ ZrO2部品

-

製品の特徴と概要

Product Line: Yttria-Stabilized Zirconia (YSZ) Ceramic Rods Material System: 3Y-TZP High-Purity Zirconia with Permanent Color Additives Manufacturing Process: Cold Isostatic Pressing (CIP), Precision Grinding, Superfinishing Quality Standards: ISO 9001, REACH/RoHS Compliant, FDA-Grade Available

Our color-coded zirconia ceramic rods utilize identical high-performance yttria-stabilized zirconia (YSZ) material across all color variations, ensuring consistent mechanical properties while enabling visual identification for streamlined inventory management and error-proof assembly. This intelligent color system allows purchasing departments to consolidate SKUs while providing engineering teams with application-specific traceability.

今すぐお問い合わせください

- shx@norkeceramics.com

-

製品説明

Core Material Advantages

- Exceptional Wear Resistance: 30x lifespan vs. hardened steel in abrasive environments

- Zero Corrosion: Inert to acids, alkalis, and organic solvents

- Thermal Shock Resistance: Rapid cycling from 20°C to 800°C without failure

- Dimensional Stability: ±0.001mm tolerance capability after precision grinding

- Low Friction Coefficient: 0.15-0.20, reducing energy consumption in moving assemblies

- Non-Conductive & Non-Magnetic: Ideal for electronics and MRI-compatible equipment

Technical Specifications

不動産 3Y-TZP Standard Mg-PSZ Option 密度 6.0-6.05 g/cm³ 5.7 g/cm³ Hardness (HV) 1250 1100 破壊靭性 10 MPa·m½ 8 MPa·m½ Max Operating Temp 500°C 800°C Bending Strength 900-1200 MPa 600-800 MPa Diameter Tolerance ±0.001mm (precision) / ±0.05mm (standard) Surface Finish Ra 0.02-0.4 μm (ground) / Ra 0.2-0.8 μm (as-sintered)

Customization & Engineering Services

Diameter Range: 0.5mm to 50mm standard, up to 100mm available

Length: Up to 300mm continuous, longer lengths via segment joining

End Features: Chamfered, radiused, threaded (M2-M12), grooved, or cross-drilled per CAD

Surface Treatments: Mirror polish, hone, DLC coating, TiN coating for extreme wear

Material Grades: 3Y-TZP (general purpose), 5Y-TZP (high strength), Mg-PSZ (thermal shock)

Color Options: Blue, black, white, pink, ivory standard; custom colors for brand identity

Packaging: Bulk trays, blister packs, serialized bags, anti-static containers

Supply Chain & Manufacturing Excellence

Monthly Capacity: 50,000 to 500,000 rods across all specifications

Prototype Lead Time: 3 weeks with DFM analysis included

Production Lead Time: 4-6 weeks for bulk orders

Quality Systems: ISO 9001, ISO 13485 (medical), IATF 16949 (automotive)

Documentation: PPAP Levels 1-5, Material Certificates, Lot Traceability, CoC

Inventory Programs: JIT delivery, consignment, VMI, Kanban integration

Global Shipping: Air freight (7-10 days) or sea freight (25-35 days)

NORKEの高精度