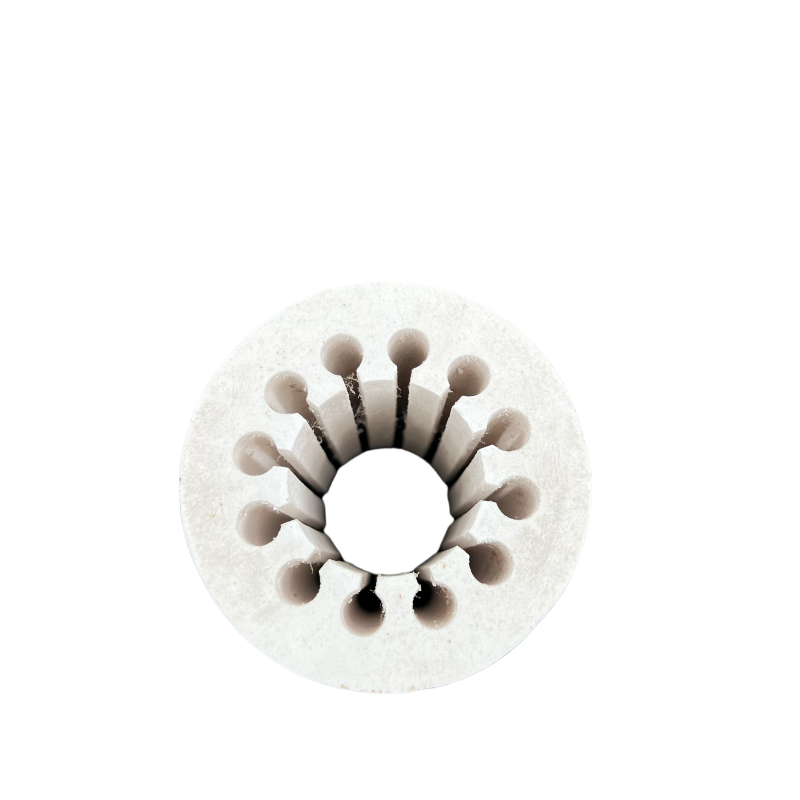

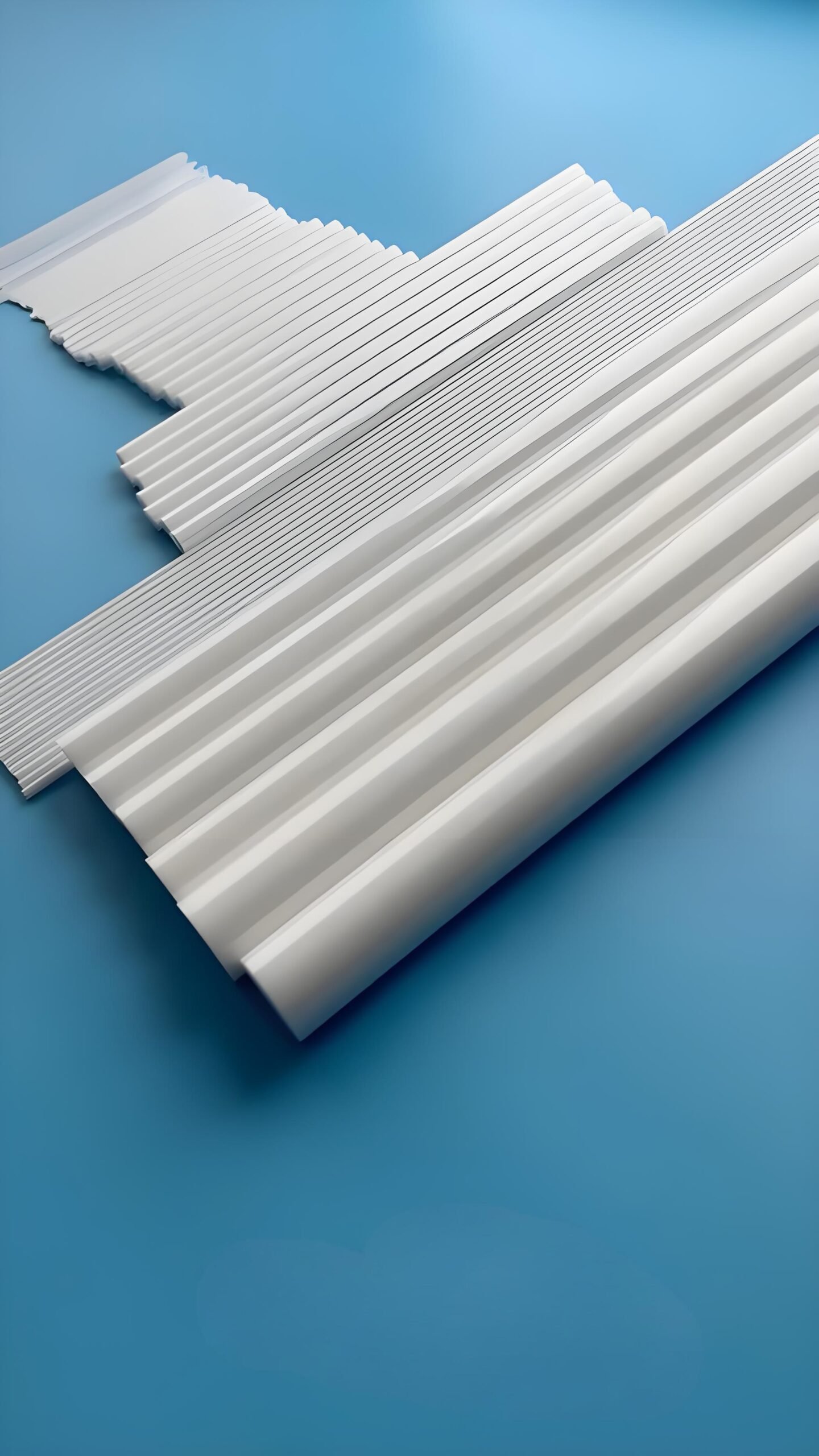

High Temperature Ceramic Fiber Special Shaped Product Refractory

-

Product Features and Brief Description

Electrothermal ceramics are specialized ceramic materials that efficiently convert electrical energy into thermal energy, characterized by high temperature resistance, corrosion resistance, and long lifespan.

Inquire Now

- shx@norkeceramics.com

-

Product Description

Electrothermal Ceramics

Electrothermal ceramics are specialized ceramic materials that efficiently convert electrical energy into thermal energy, characterized by high temperature resistance, corrosion resistance, and long lifespan.

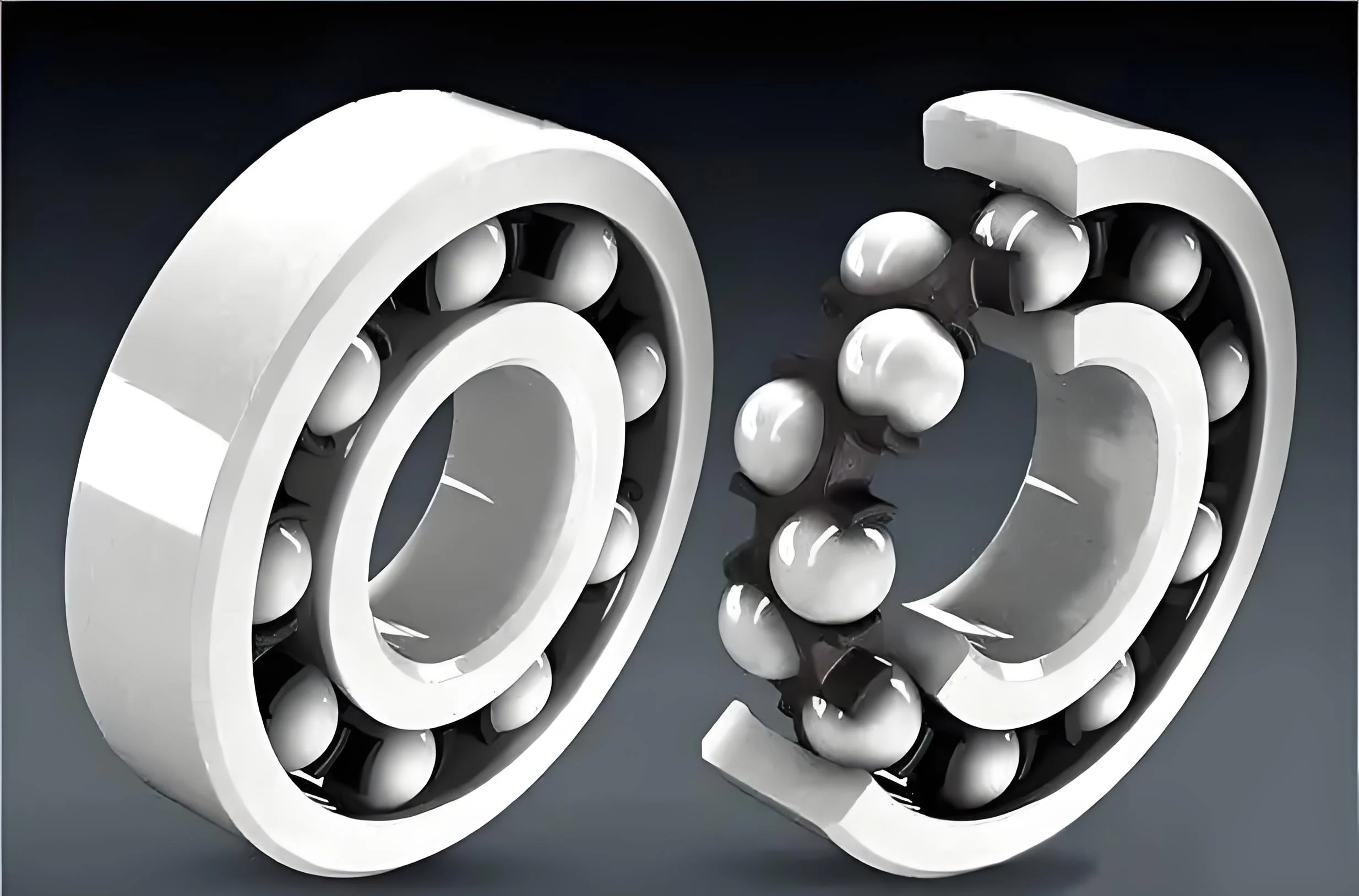

Common Types

- PTC Ceramics (Positive Temperature Coefficient Ceramics):

- Resistance increases sharply with rising temperature, offering self-regulating temperature control (e.g., barium titanate-based ceramics). Commonly used in constant-temperature heaters and electric warmers.

- NTC Ceramics (Negative Temperature Coefficient Ceramics):

- Resistance decreases with rising temperature. Primarily used in temperature sensors or current limiters.

- Other Materials:

- Silicon Carbide (SiC): High temperature resistance (up to 1600°C), used in industrial electric furnaces.

- Molybdenum Disilicide (MoSi₂): Strong oxidation resistance, suitable for high-temperature environments.

Manufacturing Process

- Raw Material Preparation: High-purity oxide (e.g., Al₂O₃, ZrO₂) or non-oxide (e.g., SiC) powders.

- Forming: Dry pressing, injection molding, or tape casting.

- Sintering: High-temperature sintering (1200-1800°C) to form a dense structure.

Advantages and Disadvantages

Advantages:

- Long lifespan (far exceeding metal heating wires).

- Corrosion and oxidation resistance.

- PTC ceramics enable automatic temperature control, enhancing safety.

Disadvantages:

- High brittleness, poor resistance to mechanical shock.

- Some materials have high costs.

- PTC Ceramics (Positive Temperature Coefficient Ceramics):

Noko

Focus on ceramic R&D and innovation

Provide your needs

Request a Quote

If you have any questions

please feel free to contact us.

Learn more about NORKE

High Precision from NORKE