The Client's Needs and Challenges

Our client, a manufacturer in the renewable energy sector, specializes in creating innovative solutions for solar and wind energy production. With the growing demand for renewable energy solutions, they faced the challenge of improving the energy efficiency and durability of their solar and wind power systems.

They sought ceramic materials that could withstand high temperatures, humidity, and mechanical stress, while also minimizing energy losses in power conversion systems. The critical requirements included:

- High-temperature resistance: Components like power converters needed materials that could operate efficiently under extreme conditions.

- Moisture resistance: The ceramics needed to endure harsh outdoor environments, such as wind turbines exposed to humidity and salt.

- Electrical insulation: The power conversion systems demanded materials that would minimize energy losses and maximize efficiency.

Our Customized Solution

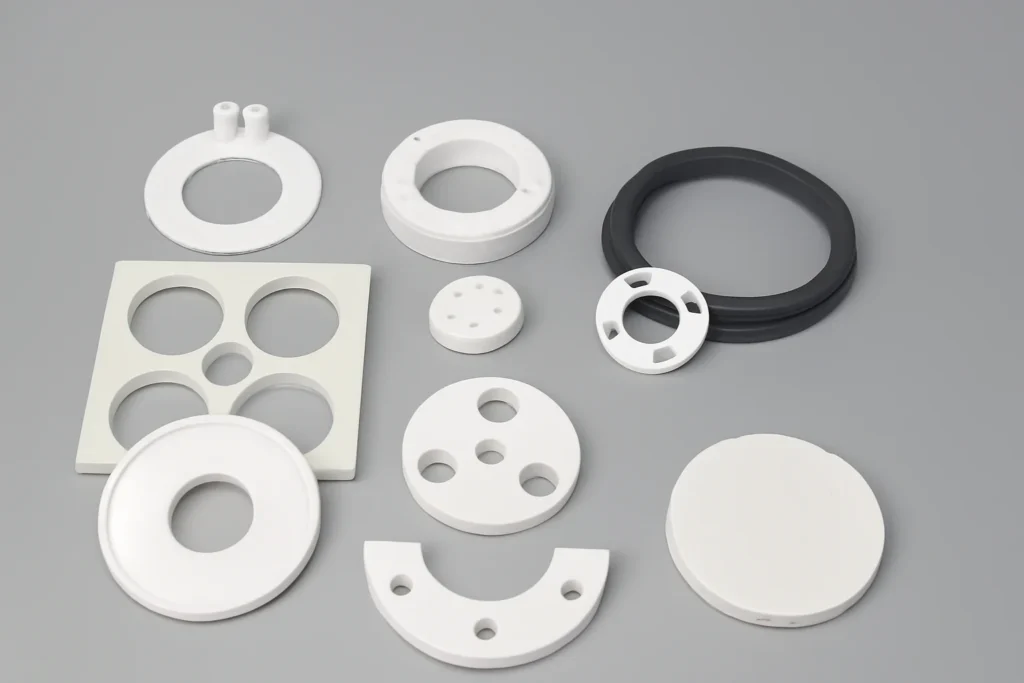

After a detailed analysis of the client's needs, the R&D team of Norke recommended semiconductor ceramics that met the following specifications:

- High Temperature Resistance: Our materials could withstand temperatures up to 300°C, ensuring that they would perform well under high thermal loads, significantly reducing the risk of overheating and failure.

- Moisture Resistance: Our ceramics had an absorption rate of less than 0.01%, making them ideal for outdoor environments and ensuring that they wouldn't corrode even after prolonged exposure to moisture or rain.

- Superior Sealing: Our customized ceramics featured sealing properties that prevented dust and contaminants from entering critical components, resulting in 60% fewer breakdowns due to external factors.

- Electrical Insulation: The ceramics offered electrical insulation with a breakdown voltage of over 1000V, which minimized energy losses in the system and optimized performance.

The Results Achieved

The client experienced the following improvements after incorporating our customized semiconductor ceramics into their systems:

- Energy Conversion Efficiency: The new materials boosted energy conversion by 12%, translating to a significant increase in the overall energy yield from both solar and wind power systems. This led to higher returns on investment for the client.

- System Durability: With enhanced moisture resistance and superior sealing, the client's systems saw 30% fewer maintenance calls in the first year. The longevity of the components was increased by 50%, extending the product lifecycle significantly and reducing the need for costly repairs.

- Operational Efficiency: By reducing energy losses through improved electrical insulation, the power systems' overall efficiency improved by 10-15%. This helped reduce operational costs for the client and allowed them to offer more competitive pricing in the renewable energy market.

- Cost Savings: The improved system durability and reduced maintenance costs saved the client an estimated $500,000 annually in repair and replacement costs.

Why Choose Norke?

At Norke, we believe in delivering high-quality, customized semiconductor ceramics that provide measurable benefits. Here’s why companies choose us:

- Expert Consultation: We collaborate closely with our clients to understand their exact needs and recommend solutions that deliver results.

- Innovative Products: Our advanced manufacturing processes ensure that our ceramics are at the cutting edge of performance and durability.

- Proven Results: With a track record of improving system efficiency by 12% and reducing maintenance by 30%, our products are proven to provide significant value.

Semiconductor ceramics are widely used in many industries, especially in communications, industrial control, energy, automotive, and medical fields. Their unique high-temperature resistance, excellent electrical insulation, and good mechanical properties make them a key material in many high-tech applications. If you’re looking to improve the performance of your systems, Norke offers the expertise and products to help you succeed. Let’s work together to power the future of renewable energy.