I. Composition and Purity

High-purity alumina ceramics: Contain over 99.9% Al₂O₃ with virtually no impurities.

Standard alumina ceramics: Classified by Al₂O₃ content as 99% alumina, 95% alumina, 90% alumina, 85% alumina, etc. Sometimes, even ceramics with 80% or 75% Al₂O₃ are categorized under standard alumina ceramics.

II. Performance Comparison

1. Hardness

High-purity type: Rockwell hardness of HRA 80-90, second only to diamond in hardness.

Standard Type: Slightly lower hardness, yet still significantly exceeds ordinary steel.

2. Wear Resistance

High-Purity Type: Exceptional wear resistance, 266 times that of manganese steel and 171.5 times that of high-chromium cast iron.

Standard Type: Good wear resistance, though inferior to the high-purity type.

3. High-Temperature Resistance

High-Purity Type: Sintering temperature reaches 1650–1990°C, suitable for higher temperatures.

Standard Type: Lower sintering temperature with slightly reduced high-temperature resistance.

4. Light Transmission

High-Purity Type: Excellent light transmission with a wavelength range of 1 to 6 micrometers.

Standard Type: Poor light transmission, primarily used for opaque components.

5. Electrical Properties

High-Purity Type: Low high-frequency loss and superior insulation properties.

Standard Type: Good electrical properties, but inferior to the high-purity type.

III. Application Scenarios

1. High-Purity Alumina Ceramics

Electronics Industry: Used for integrated circuit substrates and high-frequency insulating materials.

Lighting Industry: Manufacture of sodium lamp tubes.

Glass Industry: Replaces platinum crucibles for melting glass.

2. Standard Alumina Ceramics

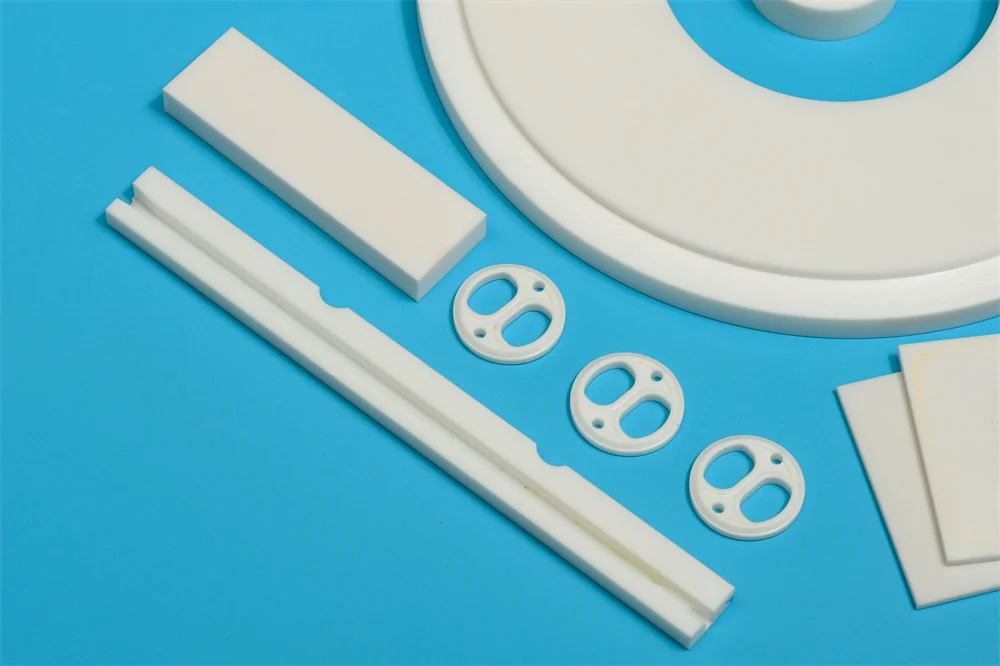

Mechanical Industry: Production of wear-resistant components such as ceramic bearings and seals.

Chemical Engineering: Used in corrosion-resistant equipment like pipelines and valves.

Electrovacuum Devices: 85 Ceramic is commonly employed in critical components of electrovacuum equipment.

IV. Cost and Processing

High-Purity Alumina Ceramics: Higher cost due to high purity and complex manufacturing processes.

Standard Alumina Ceramics: Relatively simpler manufacturing processes result in lower costs.

V. Summary

High-purity alumina ceramics and standard alumina ceramics each offer distinct advantages. Selection should balance specific application requirements and budget constraints. For scenarios demanding exceptional purity, hardness, wear resistance, high-temperature tolerance, and electrical properties, high-purity alumina ceramics are the superior choice. Conversely, standard alumina ceramics provide better cost-effectiveness in cost-sensitive applications where performance demands are not extremely stringent.

Norke’s product range includes specialized ceramic materials such as alumina ceramics, zirconia ceramics, silicon carbide ceramics, and cordierite ceramics. These products find extensive applications across various high-end industries, including electronics, machinery, chemicals, metallurgy, new energy, and semiconductors.