Piezoelectric Effect and Its Principle

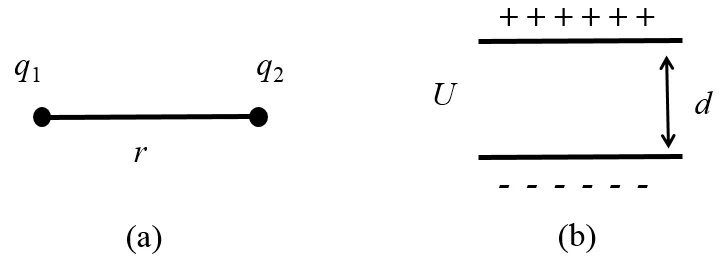

The principle of the piezoelectric effect is that applying pressure to a piezoelectric material generates an electric potential difference (known as the direct piezoelectric effect). Conversely, using an electric voltage produces mechanical stress (known as the inverse piezoelectric effect). In other words, piezoelectric ceramics possess the ability to convert mechanical energy into electrical energy and vice versa, creating a fascinating reciprocal relationship.

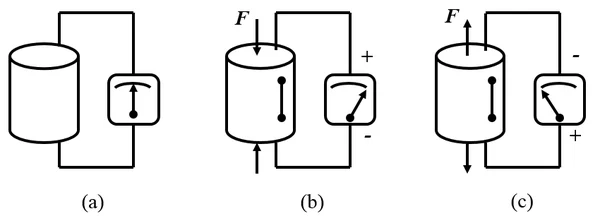

Direct Piezoelectric Effect

When a piezoelectric material is subjected to an external force in a fixed direction, internal polarization occurs, simultaneously generating oppositely charged surfaces. Upon removal of the external force, the material reverts to an uncharged state. Changing the direction of the applied force alters the polarity of the charges. The amount of charge generated is directly proportional to the magnitude of the applied force. This phenomenon is known as the direct piezoelectric effect. Most piezoelectric sensors are manufactured utilizing the direct piezoelectric effect.

Reverse Piezoelectric Effect

When an electric field is applied to a piezoelectric material, mechanical deformation occurs in specific directions, with the magnitude of deformation being proportional to the strength of the external electric field. This phenomenon is termed the reverse piezoelectric effect. Devices manufactured using the reverse piezoelectric effect find applications in ultrasonic engineering and micro-motion fields.

I. Basic Structure and Working Principle of Tubular Piezoelectric Ceramics

Tubular piezoelectric ceramics are tubular components made from piezoelectric ceramic materials. Their primary structure comprises a tubular ceramic body, an outer electrode, and an inner electrode. The outer and inner electrodes are positioned near the outer and inner surfaces of the tubular ceramic body, respectively, maintaining a specific gap between them.

Under the influence of an electric field, the differing electric fields induced by the outer and inner electrodes cause compressive deformation and distortion of the tubular ceramic body. Consequently, tubular piezoelectric ceramics exhibit piezoelectric and coupling effect properties, making them applicable in fields such as ultrasonic sensors, acoustic filters, acoustic generators, and wireless communications.

II. Vibration Direction of Tubular Piezoelectric Ceramics

The vibration direction of tubular piezoelectric ceramics is a critical issue requiring attention and resolution during design, manufacturing, and application. Vibration direction is typically defined by electrode polarity and specific application requirements. During design and manufacturing, electrode polarity and vibration direction must be determined based on the intended application and operational characteristics.

Generally, the vibration direction of tubular piezoelectric ceramics should be perpendicular to the piezoelectric direction of the ceramic material. This means that when an electric field is applied to the tubular piezoelectric ceramic, the vibration direction of the tubular ceramic body is perpendicular to the electric field direction. This arrangement effectively enhances the efficiency and reliability of tubular piezoelectric ceramics while reducing their temperature sensitivity and failure rate.

III. Application Scenarios and Operational Characteristics of Tubular Piezoelectric Ceramics

Tubular piezoelectric ceramics exhibit piezoelectric and coupling effects, with the following application scenarios and operational characteristics:

1. Ultrasonic Sensors

Tubular piezoelectric ceramics can be integrated into ultrasonic sensors. By applying an electric field to induce vibration, they convert acoustic waves into electrical signals for detection.

2. Acoustic Wave Filters

Tubular piezoelectric ceramics can be used in acoustic wave filters. By applying an electric field, they generate vibrations to filter out unwanted frequency signals.

3. Acoustic Wave Generators

Tubular piezoelectric ceramics can be used in acoustic wave generators. By applying an electric field, they vibrate to produce acoustic wave signals at specific frequencies.

4. Wireless Communication

Tubular piezoelectric ceramics can be used in wireless communication. By applying an electric field, they vibrate to convert electrical signals into acoustic wave signals for transmission.

Norke’s product range includes specialized ceramic materials. These products find extensive applications across various high-end industries, including electronics, machinery, chemicals, metallurgy, new energy, and semiconductors.