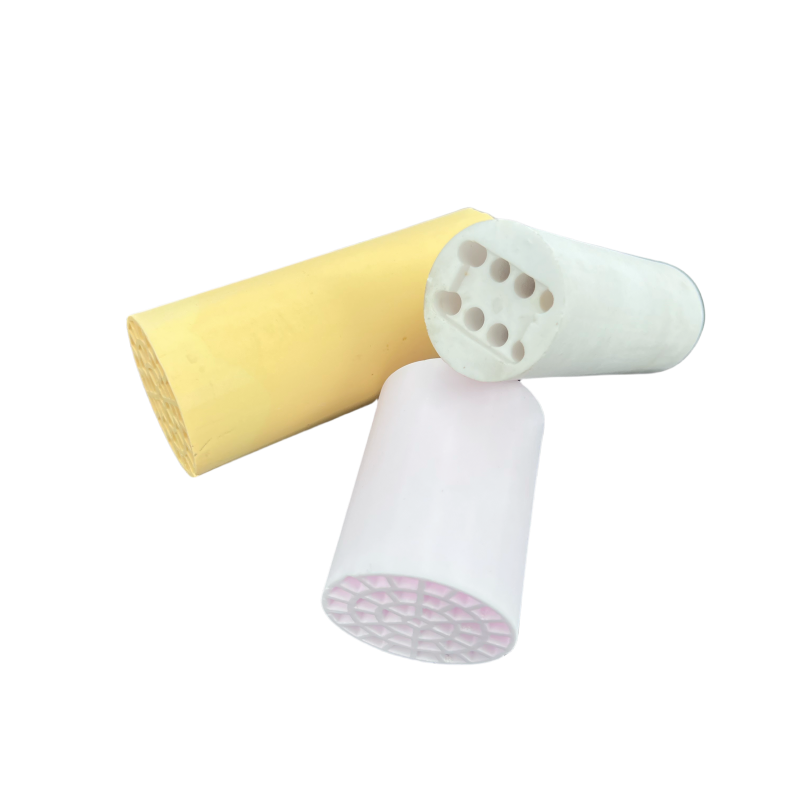

| Material | High-Performance Ceramic (e.g., Alumina, Zirconia) | Based on typical industrial ceramic materials |

| Size | Customizable based on requirements | Customized for each application |

| Outer Diameter | 10mm to 50mm (custom sizes available) | Typical range for nozzle applications |

| Height | 5mm to 30mm (custom sizes available) | Typical range for nozzle applications |

| Hole Diameter | 1mm to 5mm (customizable based on application) | Standard hole sizes used in industrial applications |

| Temperature Range | Up to 1000°C (depends on the ceramic material used) | Standard for high-performance ceramics |

| Density | ~3.0 g/cm³ (approx.) | Reference for common ceramics like alumina |

| Porosity | Low porosity for better fluid control | Typical for high-density, low-porosity ceramics |

| Compressive Strength | ~250 MPa (depending on material and design) | Based on general ceramic materials like alumina |

| Thermal Conductivity | ~20 W/m·K (varies by material type) | Typical for ceramics such as alumina and zirconia |

| Electrical Insulation | Excellent (resists electrical conductivity) | High-performance ceramics are electrically insulating |

| Packaging | Individual bubble wrap or custom foam packaging | Standard for industrial ceramic components |

| Lead Time | 15-30 days (depending on order size) | Based on production lead times for custom orders |