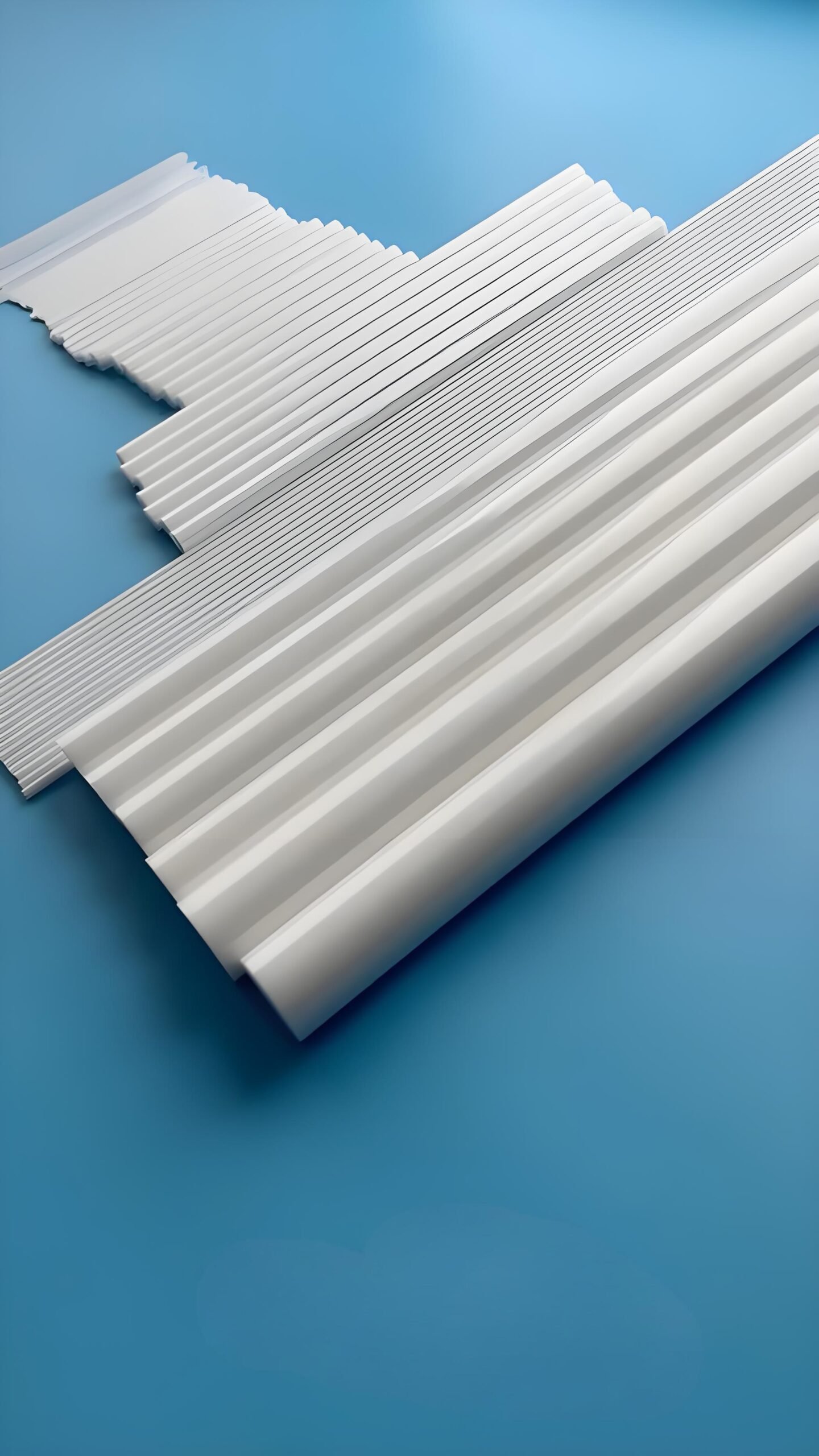

工業用グレードのイットリア安定化ジルコニア(YSZ)セラミックシリンダー|精密ZrO₂耐摩耗部品メーカー

-

製品の特徴と概要

製品カテゴリ: Technical Ceramic Cylindrical Components

Material Grade: 3Y-TZP High-Purity Yttria-Stabilized Zirconia

Manufacturing Process: Cold Isostatic Pressing (CIP) + High-Temperature Sintering + Precision Centerless Grinding

Quality System: ISO 9001:2015 Certified, FDA 21 CFR Compliant Materials Available

Engineered to solve the pain points of metal components' corrosion susceptibility and plastic parts' poor wear resistance, our zirconia ceramic cylinders deliver fracture toughness of 10 MPa·m½, Vickers hardness of 1250HV, and surface finish up to Ra 0.02μm. These components maintain zero-dimensional creep across a wide temperature range from -50°C to 500°C, enabling OEM equipment manufacturers to significantly extend equipment maintenance cycles and optimize Total Cost of Ownership (TCO).

今すぐお問い合わせください

- shx@norkeceramics.com

-

製品説明

Technical Specifications & Selection Parameters

Performance Parameter Standard Grade (3Y-TZP) Enhanced Grade (5Y-TZP) 材料組成 ZrO₂ + 3 mol% Y₂O₃ ZrO₂ + 5 mol% Y₂O₃ 密度 6.05 g/cm³ 6.00 g/cm³ Hardness 1250 HV₁₀ 1150 HV₁₀ Flexural Strength 900-1200 MPa 800-1000 MPa 破壊靭性 10 MPa·m½ 12 MPa·m½ Maximum Service Temperature 500°C continuous 500°C continuous Dimensional Tolerance ±0.001mm (precision) / ±0.05mm (as-sintered) Surface Roughness Ra 0.02μm (superfinish)

Industry Applications & Technical Solutions

1. Fluid Handling & Chemical Processing Equipment

Application Scenarios: Metering pump plungers, corrosion-resistant valve stems, seal face bushings

Technical Value: Achieves zero corrosion in strong acid media; extends seal face service life from 3 months (traditional materials) to 18 months; meets FDA validation requirements for pharmaceutical companies, preventing metal ion contamination of API raw materials and ensuring cGMP compliance.2. High-Speed Precision Machine Tools

Application Scenarios: Spindle locating sleeves, linear guide bushings, fixture locating pins

Technical Value: Maintains ±0.5μm repeatability at 20,000 RPM; supports dry running operation, eliminating lubricant procurement and waste disposal costs; aligns with environmentally-friendly manufacturing requirements.3. Thermal Processing Industrial Furnaces

Application Scenarios: Vacuum furnace support posts, heat treatment tooling fixtures, brazing locating blocks

Technical Value: Zero thermal deformation at 500°C; increases tooling lifespan from 6 months (metal) to 3 years; low thermal conductivity reduces heating cycle time by 30%, cutting industrial furnace energy costs.4. Analytical Instruments & Testing Equipment

Application Scenarios: Mass spectrometer insulator columns, chromatography plungers, autosampler positioning rods

Technical Value: Non-magnetic interference ensures electron optics detection accuracy; chemical inertness is compatible with all mobile phases; extends instrument maintenance intervals, reducing MRO procurement frequency.5. Medical Device Manufacturing

Application Scenarios: Surgical instrument handle cores, dental handpiece internal shafts, implantable device housings

Technical Value: ISO 10993 biocompatibility certified; withstands 1,000+ autoclave cycles; material radiopacity enables intraoperative X-ray positioning, enhancing surgical safety.

Mass Production & Supply Chain Control Capabilities

Monthly Production Capacity: 50,000 to 500,000 pieces, supporting continuous, stable supply for high-volume orders

Sample Delivery: First article samples within 3 weeks, including a free DFM analysis report

Production Lead Time: 4-6 weeks for standard bulk orders, 2 weeks for urgent orders (rush fee applies)

Quality Certifications: ISO 9001, ISO 13485 (medical), IATF 16949 (automotive)

Process Control: 100% laser dimensional inspection, SPC process capability monitoring, Cpk≥1.67

Document Package: PPAP files (Levels 1-5), material certificates, lot traceability records, CoC (Certificate of Conformance)

Enterprise Procurement & Technical Support Services

Selection Consultation: A Professional technical engineering team provides free material selection and failure analysis services, assisting equipment manufacturers in optimizing design schemes

Inventory Management: Supports Kanban replenishment, consignment inventory (VMI), long-term agreement price protection, ensuring supply chain stability for procurement departments

Partnership Models: Accepts annual framework agreements with locked pricing and capacity, allows exclusive supply terms

Customization Capability: OEM/ODM capability for non-standard designs, Minimum Order Quantity (MOQ) 1,000 pieces

After-Sales Guarantee: Free replacement for material defects during the warranty period, covers consequential damages caused by quality issues

Cross-Material Performance Comparison (TCO Analysis)

Comparison Parameter Zirconia Ceramic Cylinders 440C Stainless Steel PEEK Engineering Plastic Wear Resistance (Relative Life) ★★★★★ (30x) ★★★☆☆ (1x) ★★☆☆☆ (0.5x) Chemical Resistance (Chemical Range) Universal Inertness Partial Acid Corrosion Swelling in Strong Acids Maximum Operating Temp. (Continuous) 500°C 300°C 260°C Dimensional Accuracy Retention ★★★★★ ★★★☆☆ ★★☆☆☆ Total Lifecycle Cost 40-60% Reduction Baseline 20-30% Reduction Suitable Batch Scale Medium to High Volume High Volume Low Volume

NORKEの高精度