High Temperature Ceramic Fiber Special Shaped Product Refractory

-

製品の特徴と概要

Electrothermal ceramics are specialized ceramic materials that efficiently convert electrical energy into thermal energy, characterized by high temperature resistance, corrosion resistance, and long lifespan.

今すぐお問い合わせください

- shx@norkeceramics.com

-

製品説明

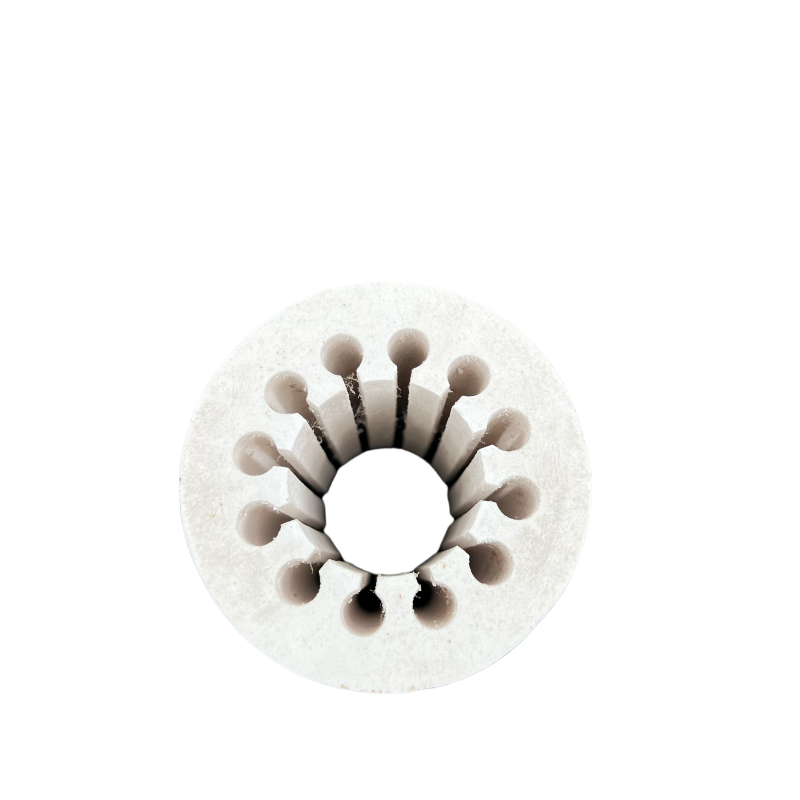

Electrothermal Ceramics

Electrothermal ceramics are specialized ceramic materials that efficiently convert electrical energy into thermal energy, characterized by high temperature resistance, corrosion resistance, and long lifespan.

Common Types

- PTC Ceramics (Positive Temperature Coefficient Ceramics):

- Resistance increases sharply with rising temperature, offering self-regulating temperature control (e.g., barium titanate-based ceramics). Commonly used in constant-temperature heaters and electric warmers.

- NTC Ceramics (Negative Temperature Coefficient Ceramics):

- Resistance decreases with rising temperature. Primarily used in temperature sensors or current limiters.

- Other Materials:

- Silicon Carbide (SiC): High temperature resistance (up to 1600°C), used in industrial electric furnaces.

- Molybdenum Disilicide (MoSi₂): Strong oxidation resistance, suitable for high-temperature environments.

Manufacturing Process

- Raw Material Preparation: High-purity oxide (e.g., Al₂O₃, ZrO₂) or non-oxide (e.g., SiC) powders.

- Forming: Dry pressing, injection molding, or tape casting.

- Sintering: High-temperature sintering (1200-1800°C) to form a dense structure.

Advantages and Disadvantages

Advantages:

- Long lifespan (far exceeding metal heating wires).

- Corrosion and oxidation resistance.

- PTC ceramics enable automatic temperature control, enhancing safety.

Disadvantages:

- High brittleness, poor resistance to mechanical shock.

- Some materials have high costs.

- PTC Ceramics (Positive Temperature Coefficient Ceramics):

NORKEについて詳しく知る

NORKEの高精度