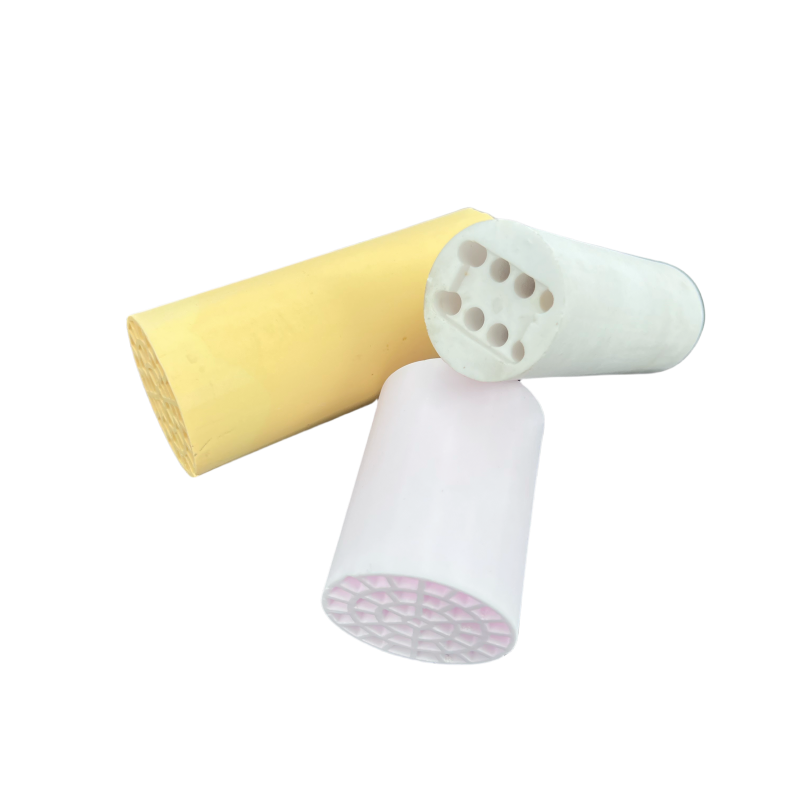

Our Cordierite Ceramic Kiln Furniture Support is specially designed for high-temperature industrial firing processes. Made from high-purity cordierite material, this ceramic support holder provides excellent thermal shock resistance, low thermal expansion, and stable structural strength even under repeated rapid heating and cooling cycles.

This component is widely used to support, position, and stabilize ceramic parts during sintering, calcination, and high-temperature processing. It is commonly applied in honeycomb ceramic production, technical ceramics, spark plug ceramics, advanced electronic ceramics, and many other precision firing processes.

Its optimized geometric structure ensures uniform load distribution, reduced deformation, and extended service life of kiln furniture systems, helping improve loading efficiency and reduce operating energy consumption.

For Industrial Buyers & OEM Projects We support long-term supply, stable batch consistency, customized geometry based on kiln loading design, and technical coordination for thermal process engineers.