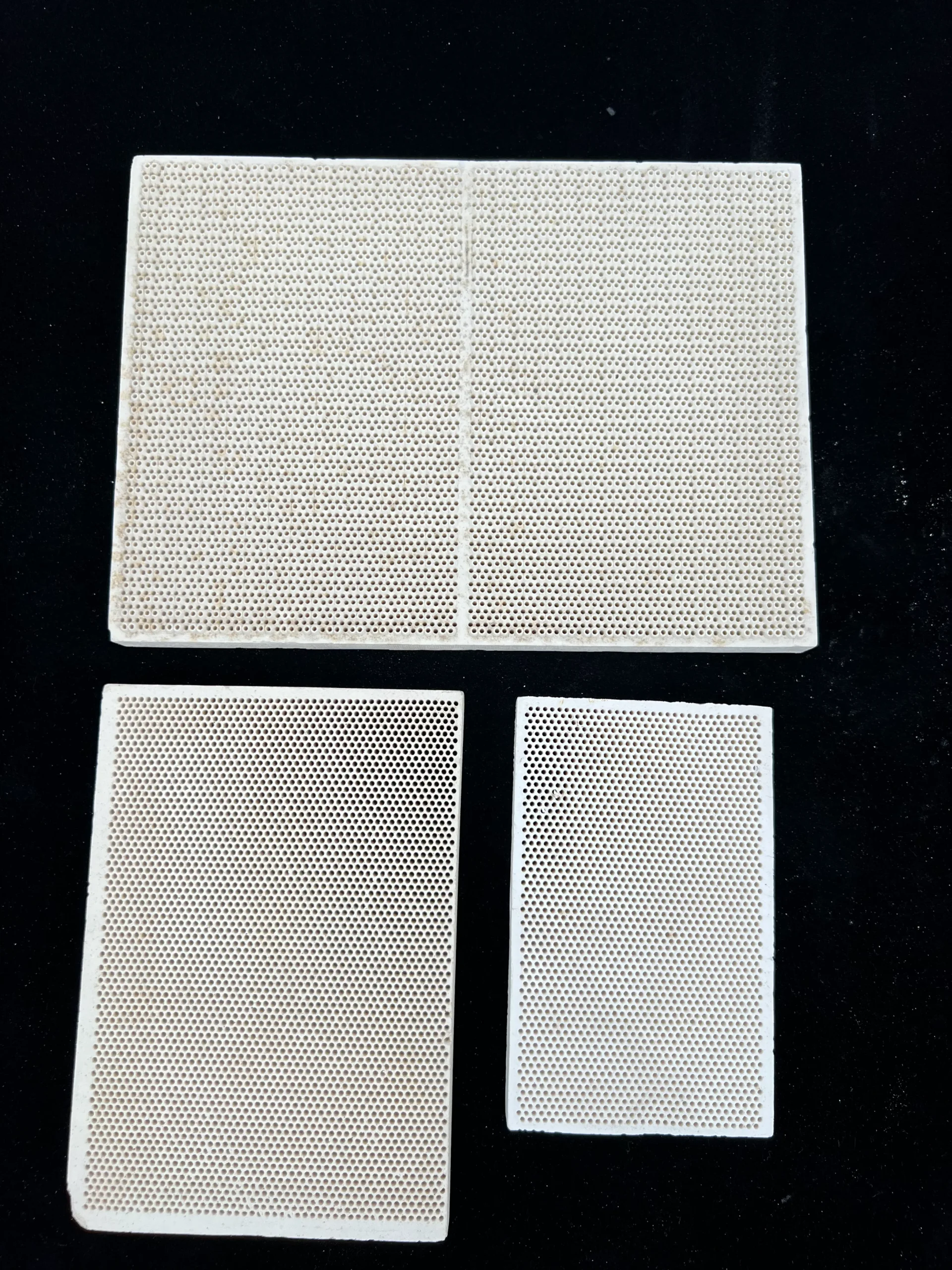

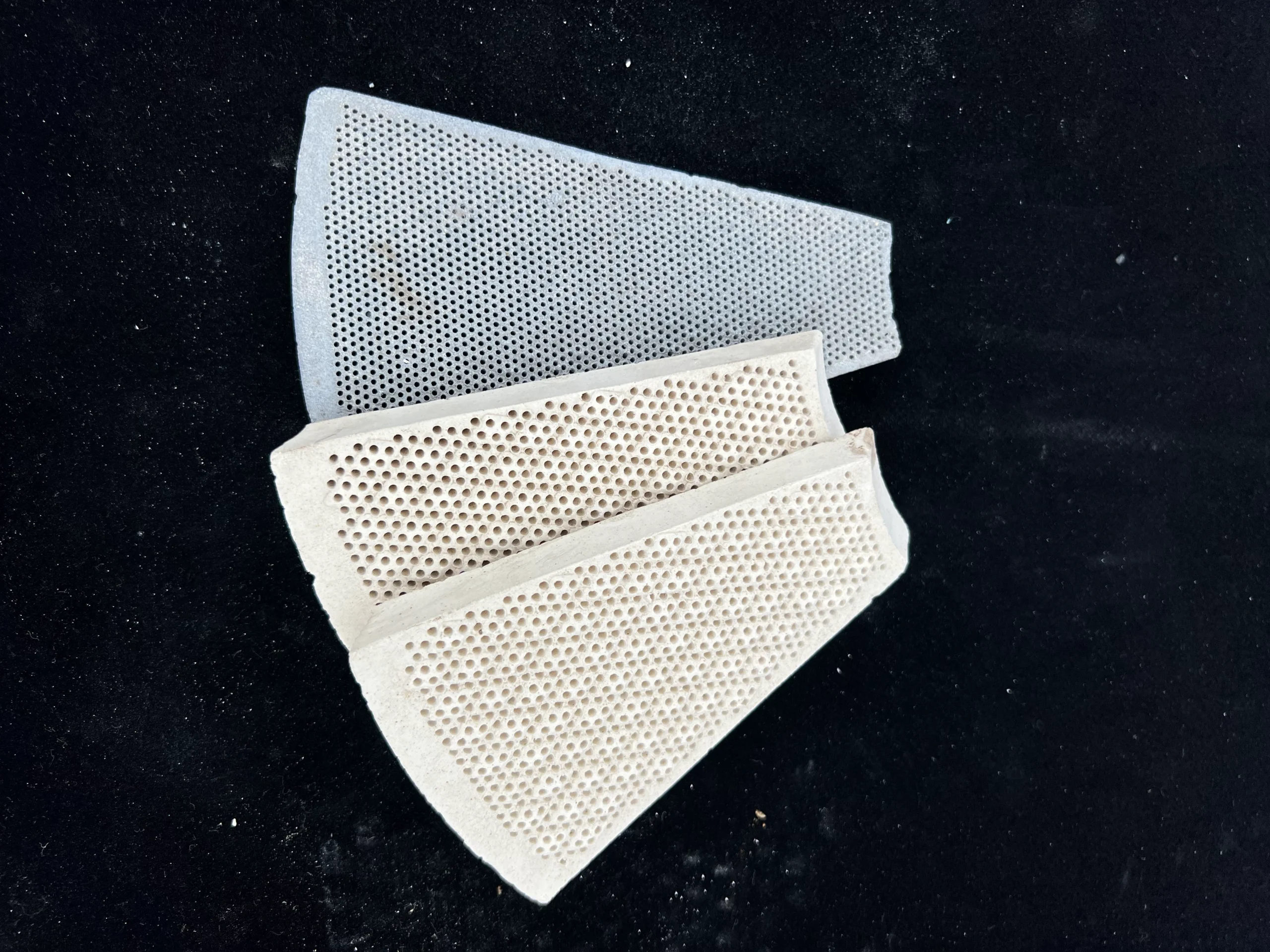

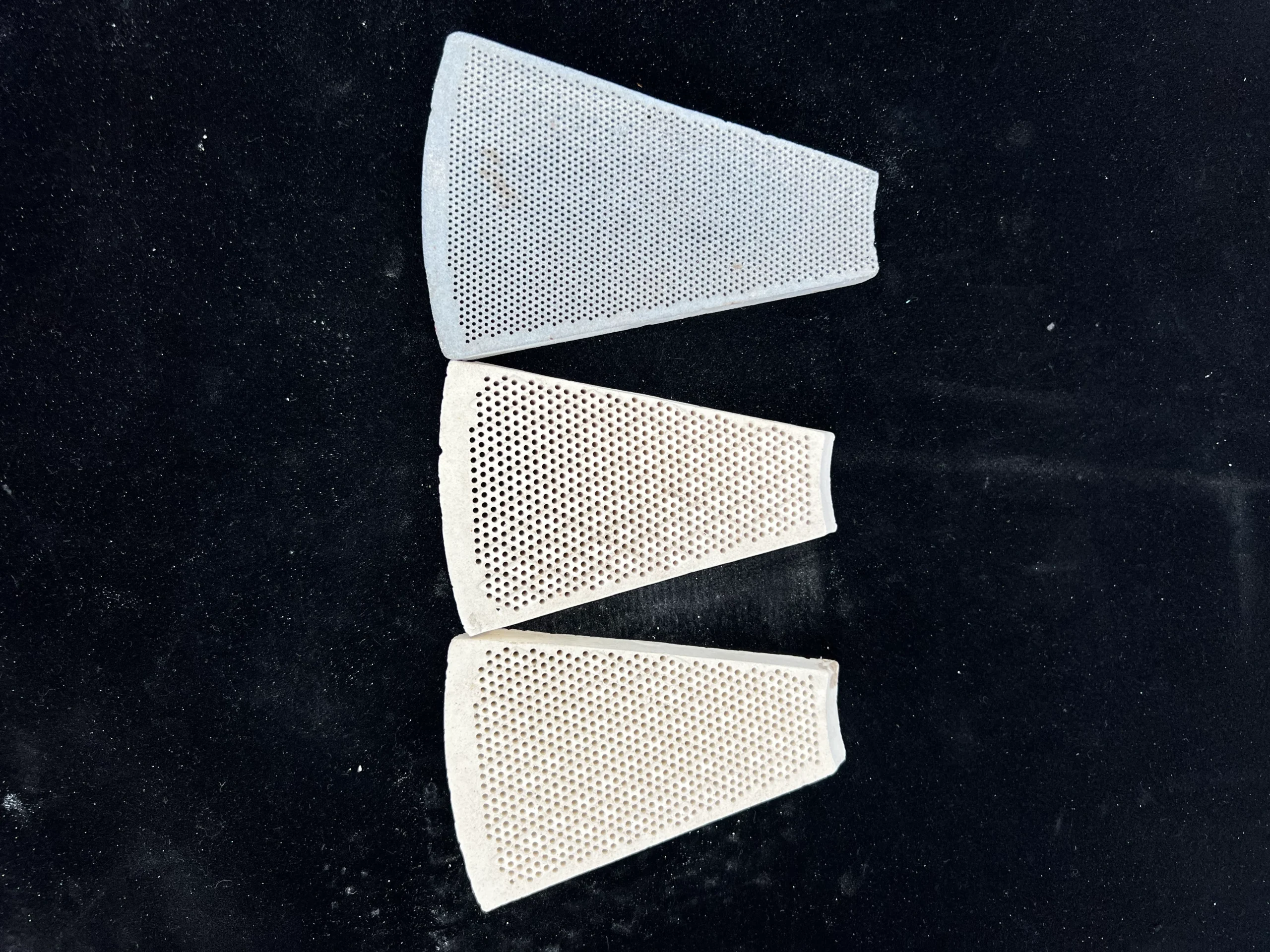

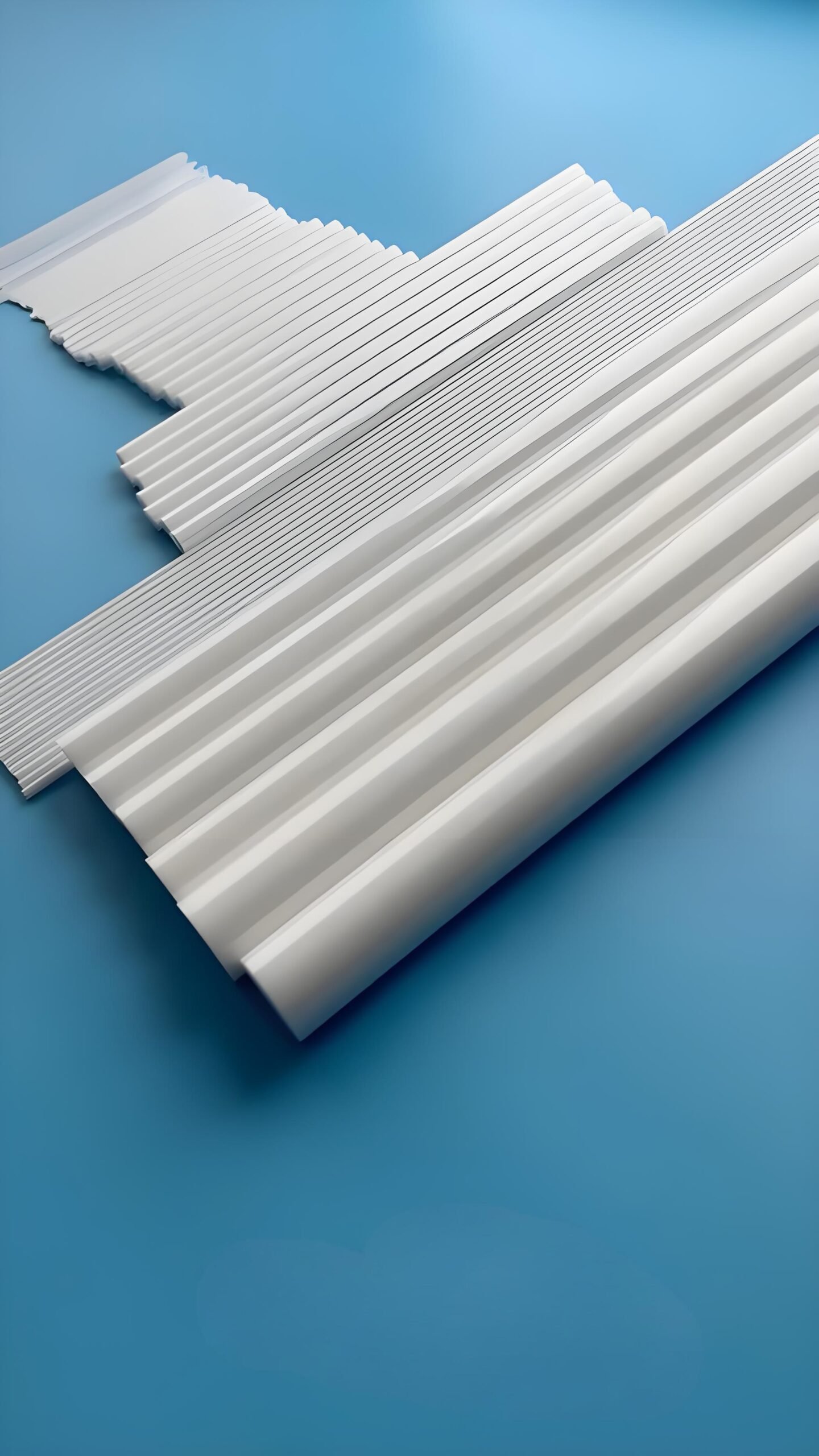

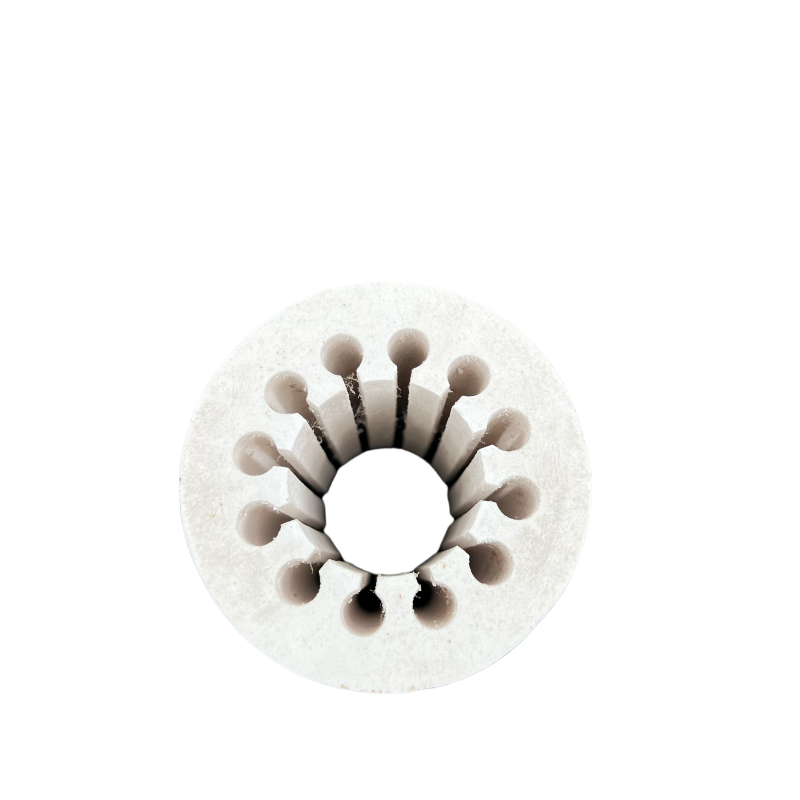

Our High-Temperature Cordierite Ceramic Sheets, Far-Infrared Honeycomb Ceramic Panels, and Refractory Heat Exchange Ceramic Plates are engineered to provide exceptional performance in demanding industrial applications. These advanced ceramic products are ideal for industries requiring high-temperature resistance, energy-efficient heat transfer, and thermal insulation.

These ceramic sheets are designed to withstand temperatures up to 1450°C, making them perfect for kilns, furnaces, heat exchangers, and industrial heating systems. The honeycomb ceramic panels are optimized for far-infrared radiation, ensuring high-efficiency heating and energy savings. Meanwhile, our refractory heat exchange ceramic plates offer superior thermal conductivity, ensuring efficient heat transfer in high-heat environments.

Our products are crafted from premium cordierite et refractory ceramics, providing excellent thermal shock resistance, durability, and low thermal expansion, even under extreme operating conditions. Whether you need fireproof ceramic panels for your industrial equipment or high-performance ceramic sheets for heat exchange systems, our products are built to perform reliably over the long term.

With customizable sizes and configurations, our ceramic panels et heat exchange plates are the perfect solution for a wide range of industrial applications in sectors like metallurgy, automotive, power generation, and aerospace.