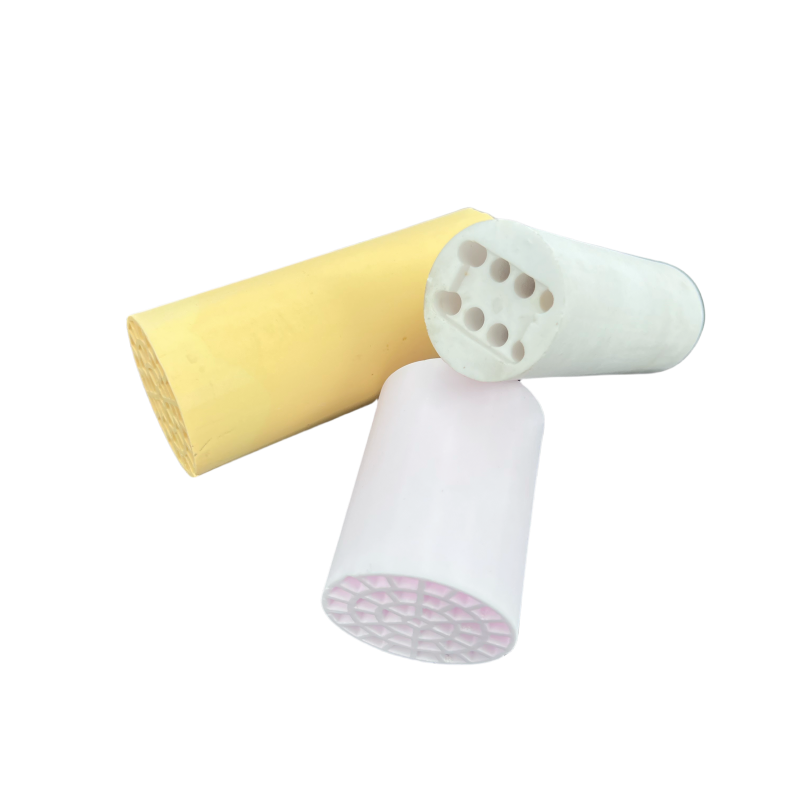

The cordierite ceramic support disc is used as an insulating and positioning component in industrial electric heating systems. It provides stable support and separation for heating coils, resistance wires, and alloy heating elements during long-term operation under elevated temperatures.

Cordierite features a low thermal expansion coefficient and excellent thermal shock resistance, ensuring dimensional stability during repeated temperature cycling. The material maintains high electrical insulation performance, preventing short circuits or contact failures in compact heater assemblies.

This component is suitable for electric heating tubes, air heaters, industrial blowers, drying and thermal processing equipment, and can be customized with different diameters, hole patterns, and tolerance grades to match specific heater designs and installation requirements.

Customization & Supply Capability

- Support drawing-based manufacturing

- Tolerance control for automated heater assembly

- Consistent batch production for OEM and industrial system integrators

- Export packaging suitable for long-distance transport and warehouse storage